Our products

Home » Cable protection pipes » SRE-P Cable protection pipes

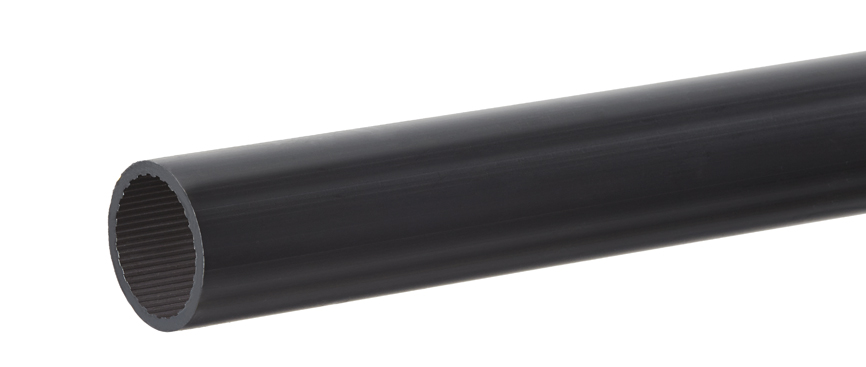

SRE-P cabel protection pipes with grooved interior.

Cabel protection pipe SRE-P (protection, pipes, extra difficult conditions – plastic)

Cabel protection pipe SRE-P (protection, pipes, extra difficult conditions – plastic)

Pipes for extra rough terrain

Our cable protection pipes are specially designed for tougher terrain where high strength is a requirement. They are manufactured from high density polyethylene (PEHD) and have a ring stiffness (over 16 kN) that is significantly higher than standard requirements (8 kN). The pipes have a high resistance to external pressure and stress and are also resistant to most chemicals. They are also sealed to prevent the penetration of ground water and soil or sand. Quite simply, Extena’s cable protection pipes provide highly reliable protection for electrical cables – and thus offer optimal weather protection.

SRE-P (protection, pipes, extra difficult conditions – plastic) is used for surface laying in difficult terrain.

Grooved interior

Extena’s SRS and SRE-P cable protection pipes have a grooved interior to reduce friction when pushing through power cables. We see this as a big advantage. The use of cable protection pipes instead of a sand bed also provides more efficient propulsion, safer pipelaying and lower total costs.

Quality at every stage

Our products undergo very thorough quality control, both in our own testing laboratory and at external inspection institutes. In this important task, we collaborate closely with the research Institute RISE. Another aspect of our quality assurance is that we have full traceability of the materials that we use.

Safe supplier for large projects

We have extensive experience of large projects and know how important the time aspect and reliability of supply are when working with many subcontractors. Since we have our own modern, large capacity production facility and a complete range of polyethylene pressure pipes and pipe fittings, we are now a reliable supplier to large projects all over Sweden. We are a safe partner in marine pipeline projects and the expansion of municipal water supply systems, for example.

Product benefits

- Cable protection pipe SRE-P made of PEHD.

- Extena cable protection pipes have a higher ring stiffness than specified in the standard. Over 16 kN instead of 8 kN.

- The pipes have a grooved interior for reduced friction and easier pushing through.

- The use of cable protection pipes instead of a sand bed provides more efficient propulsion, safer pipelaying and lower total costs.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for trench-free pipelaying.

Approvals/Certificates

SPF work standard 5200 issue 1 – EBR standard KJ41:15 – SPKB 1992:06

Facts

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Delivery options

Coil

Drum

Straight lengths

6, 12, 18, or 20 m

- All pipes are fitted with end caps

- Non-standard lengths can be ordered on request