KIWA

Certification and testing of e.g. plastic pipes with vapour barriers.

Kiwa is one of the world’s 20 largest companies specializing in inspection, testing and certification. Kiwa provides a variety of services such as technical consultation and training. Kiwa was founded in 1948 in the Netherlands but over the years has grown to become a leading player in the field. In 2008, Kiwa acquired the Swedish SWEDCERT and thereby expanded into the Swedish market. Kiwa currently employs more than 4,500 people in over 40 countries, mainly in Europe, Asia and South America.

Extena SLA® Barrier Pipe samt 3L Leak Control Extena SLA Barrier Pipe and 3L® Leak Control are tested and approved by KIWA and meet the requirements for vapour tight pipes.

Extena SLA® Barrier Pipe samt 3L Leak Control Extena SLA Barrier Pipe and 3L® Leak Control are tested and approved by KIWA and meet the requirements for vapour tight pipes.

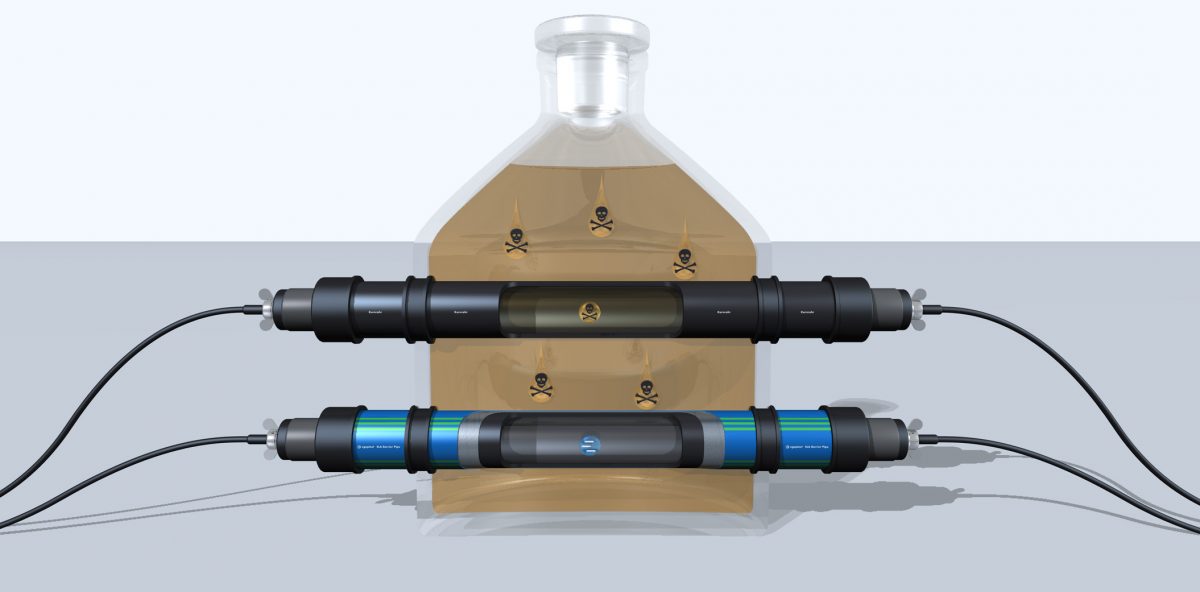

Test rig (KIWA) used to test SLA Barrier Pipe and 3L® Leak Control together with homogeneous polyethylene pipes.

Vapour tight barrier tests

SLA® Barrier Pipe och 3L® Leak Control är certifierade av KIWA, klass III (högsta klass) efter bland annat långtidstester avseende diffusion och påverkan av till exempel TCE (Trichloroethylene). Kravet är att rörsystem skall klara en livslängd på minst 50 år. Genom beräkningar kan SLA® Barrier Pipe och 3L® Leak Control stå emot genomträngning även efter 100 år. Baserat på dessa tester och beräkningar är SLA® och 3L® certifierade av KIWA (BRL-K 170101).