Our products

egeFuse 2.0 gravity pipeline SN16 for surface and waste water

Gravity pipes made of PE100. Pipe system with extra high ring stiffness (SN16 instead of SN8) and welded joints using pre-assembled arc welding sleeves. Dim ø 280-630 mm

egeFuse 2.0 made of PE100 is probably the safest gravity pipeline on the market. Its high strength ring stiffness (SN16) combined with welded joints provides a pipeline with unique properties.

egeFuse 2.0 has a stiffness class of SN16, which is twice the ring stiffness of traditional SN8 ground sewers in class SN8. The pipe is also fitted with arc welding sleeves. Welded joints avoid the risk of root penetration, which can cause leaks. It also provides safer joints when laying in unstable ground and a completely sealed pipeline.

Safe joints

The egeFuse 2.0 is equipped with an arc welding sleeve. Since the pipe has the same outside diameter as a traditional pressure pipe, traditional arc welding sleeves can also be used in cases where the pipes need to be cut.

Resistance to external impact

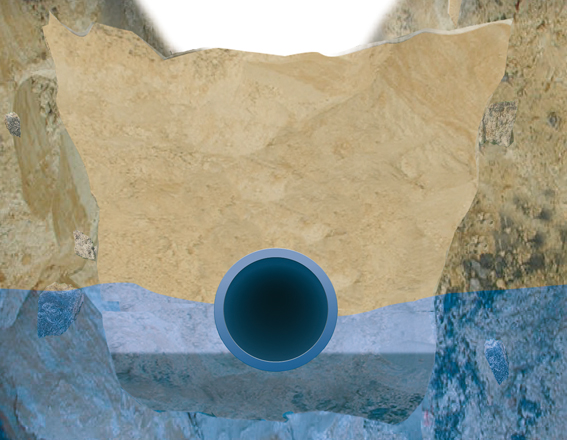

Gravity pipes are affected by external loads throughout the service life of the pipeline. This may be soil and traffic loads, but also groundwater pressure. At greater laying depths, the pressure from soil load has a big impact, while traffic load has the biggest impact on pipelines laid closer to the surface. Settlement in the pipe trench also affects the service life and function of the pipeline. Unstable soils such as loose clay can cause settlement quite easily, which in turn can affect the function of the pipeline.

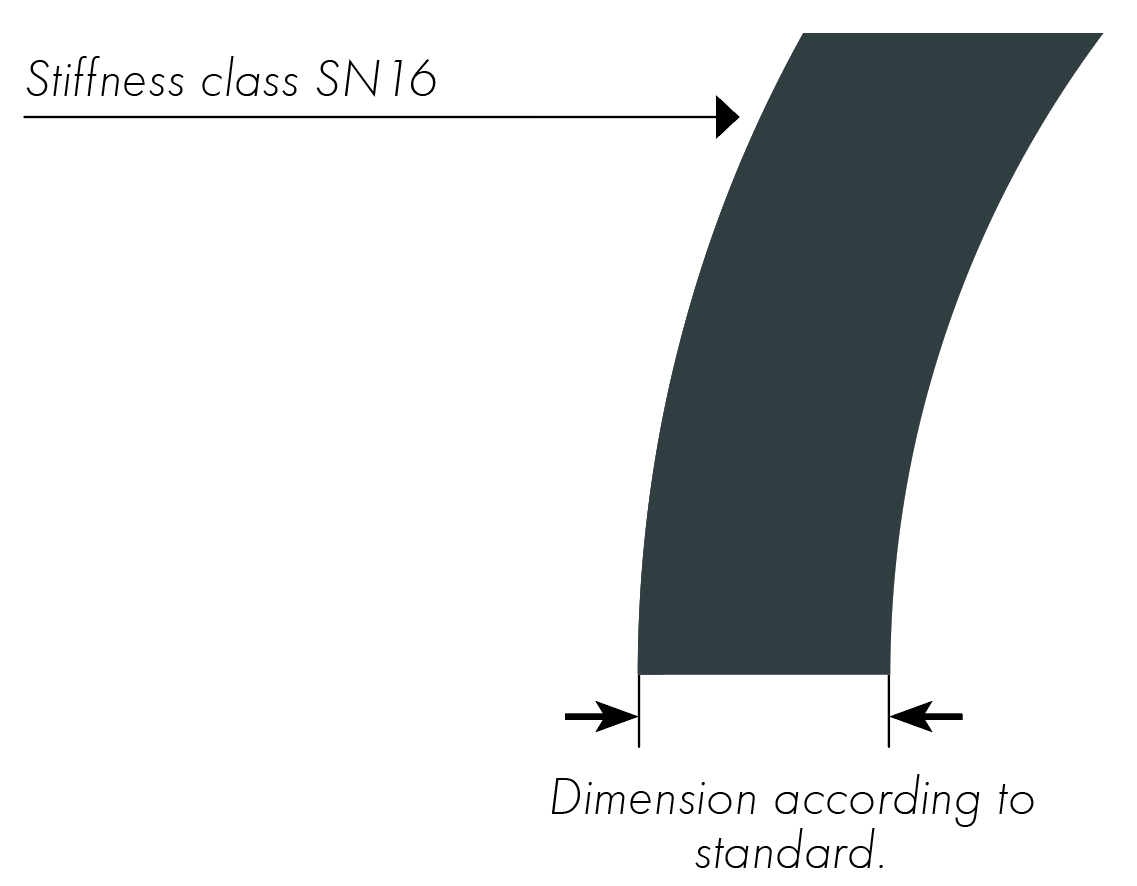

Stiffness class SN16

Gravity pipes are divided into different SN classes (nominal stiffness) depending on the short-term stiffness of the pipe according to EN ISO 9969 and these are given in kN/m2. Standardized stiffness classes are SN2, SN4, SN8 and SN16. Ring stiffness describes the deformation characteristics of a pipe. A pipe with a high ring stiffness has less impact in terms of ovality than a pipe with a low ring stiffness.

High ring stiffness combined with high compression during pipelaying gives minimal deformation. Stiffness class SN8 is normally used for gravity pipes. Since the actual cost of the pipe normally represents only 5-15% of the total pipelaying cost, it is better to choose a pipe with the highest possible stiffness class if this is justified.

Under normal pipelaying conditions, it is possible to use pipes with stiffness class SN8, but when laying in unstable soils, in areas with large traffic loads, in deep trenches with a high soil load or in ground with external high water pressure, we recommend eFuse.

Areas with heavy truck traffic and the mining industry are two suitable applications for egeFuse 2.0. The high strength ring stiffness of the pipes SN16 instead of the normal SN8 (which applies to traditional ground sewers), combined with built-in arc welding sleeves, provides a safe pipeline network that can withstand very high loads.

Product benefits

- Surface and waste water pipes for gravity pipes made of PE100.

- Intended for high water pressure or pipelaying where heavy loads are present, such as timber lorries and heavy trucks.

- Welded joints with arc welding sleeves.

- No risk of root penetration which can cause leaks.

- Same outside diameter as traditional pressure pipes.

- egeFuse 2.0 offers safer gravity pipelines for surface and waste water.

- White interior facilitates inspection such as filming.

Pipelaying method

Traditional pipelaying in trenches.

Suitable for pipelaying where there is a risk of root penetration.

Suitable for pipelaying under heavy traffic or soil loads.

Suitable for pipelaying where there is a risk of high water pressure or unstable soils.

Facts

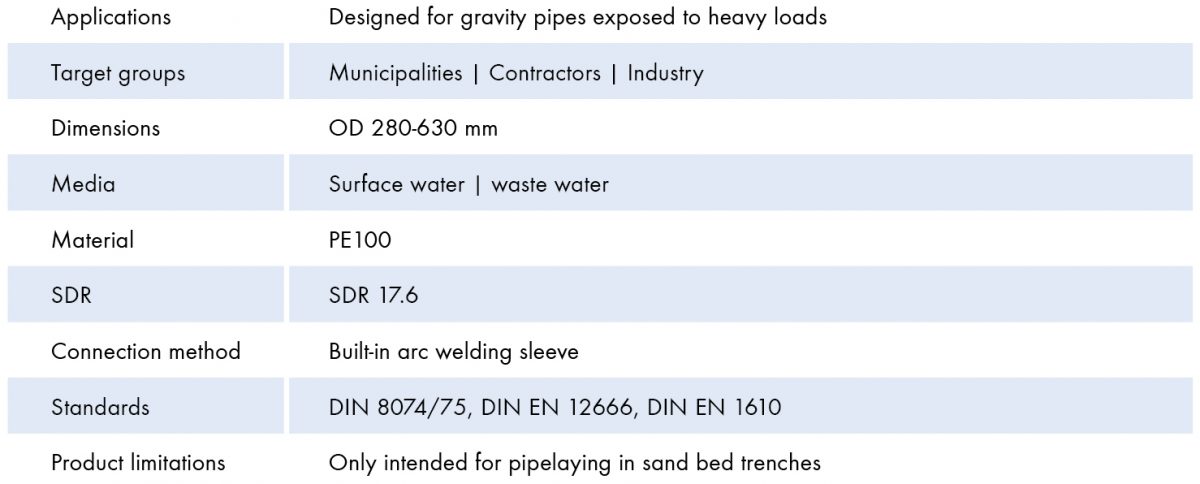

Pipe fittings

PE pipe fittings

– Injection moulded

– Seamless

– Machined

– Segment welded

Arc welding parts

Complete range of arc welding parts for different purposes.

Flange joints

Wide range of flange joints such as loose flanges, SF flanges and HP flanges.

Custom pipe fittings

A range of customized pipe fittings is available for egeFuse 2.0.

Delivery options

Straight lengths

(3 or 6 m)

- Standard lengths 3 and 6 metres.

- Longer lengths on request